For more than 20 years of activity in the field of progress cavity pumps, we have built up experience that has enabled us to launch our own brand of pumps “AFT NOVAROTORS”. NovaRotors Srl is a leading manufacturer of progress cavity pumps on the Italian market with many years of experience in pump manufacturing, its own design team and extensive production facilities.

The wide range of AFT NOVAROTORS pumps, combined with our experience in technical consulting, allows us to comprehensively meet the requirements of any installation.

AFT NOVAROTORS pumps are both customized solutions and proven, mass-produced units for typical applications.

Files to downloadProducts

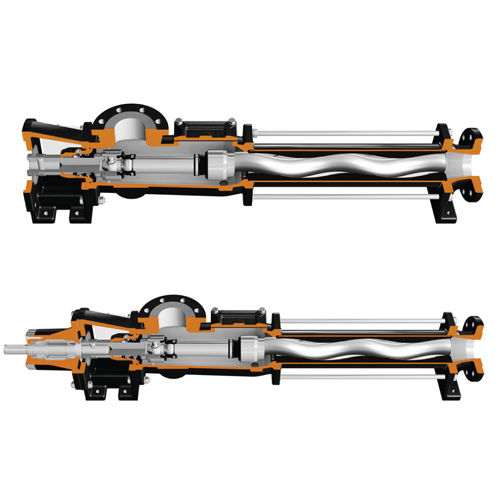

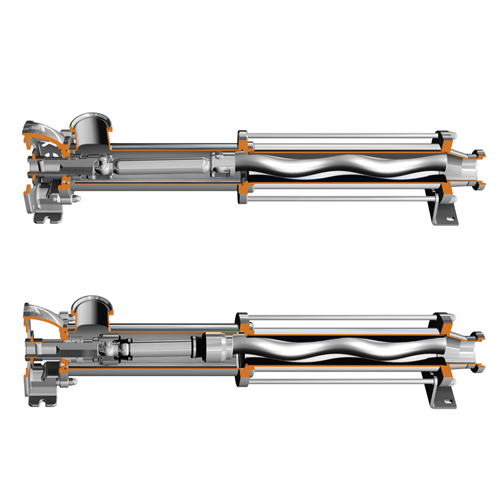

Standard cavity pumps

DN and JN series

Capacity: 30l/h – 500 m3/h

Pressure up to 48 bar

Mounted vertically or horizontally

Modularity allowing adaptation to the existing installations

Low pulsation, uniform flow

Easy change in the flow direction allowed

simply by changing the direction of the rotation

Hygienic cavity pumps

DXO and DXC series

Capacity: 30l/h – 300 m3/h

Pressure up to 48 bar

Mounted vertically or horizontally

Modularity allowing adaptation

to the existing installations

Open joint for maximal hygienic standard

and closed joint for the highest durability

Ready for CIP/SIP cleaning

Completely free of dead zones

Compliance with FDA, EHEDG and 3A

Metering pumps

DM series

Capacity 0,1l/h – 30l/h

Pressure up to 24 bar

Modularity allowing adaptation

to required conditions

Accurate dosing without pulsation

or the use of control valves

Constant flow, independent of pressure

Best chemically resistant solutions

Macerators

TG series

Flow rate 1 m3/h – 100 m3/h

Two inspection ports as standard

Series of hardened knifes mounted

on two counter-rotating shafts

Simple maintenance,with easy access

to the cutting chamber

Easy access to the inside of the cutting chamber

Additional equipment: control panel,

stone separator and many more

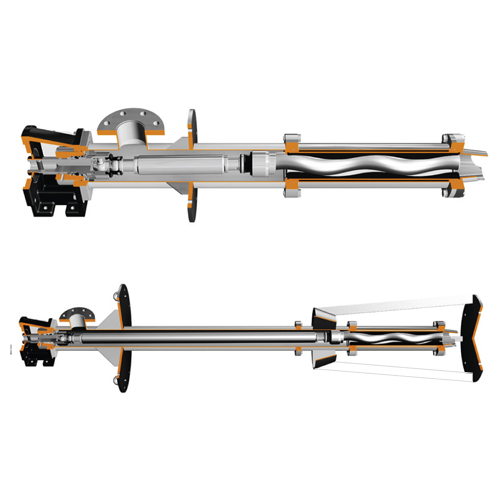

Submersible cavity pumps

DV series

Capacity: 30l/h – 150 m3/h

Pressure up to 12 bar

Variable immersion depth suitable

for application requirements

In the short and long version,

with an additional stabilizing base plate

Allows complete emptying of tanks

(pumping from the bottom with no product loss)

Ideal solution where NPSHa is limited

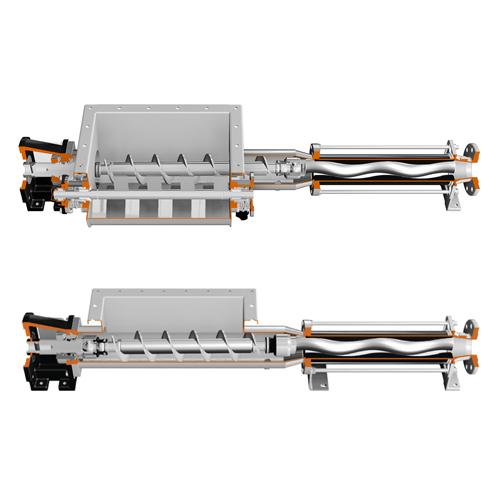

Cavity pumps with hopper

Series DH and JH

Capacity: 50 l/h – 500 m3/h

Pressures up to 36 bar

Pumping of products with high

viscosity and low flowability

Possibility to adjust the hopper

to individual requirements

Stroke and diameter of the feed screw

are adapted to conditions

Various pump variations are possible such as with

integrated trolley, built-in hopper with integrated

bridge breaker, with integrated feed screw