DICKOW PUMPEN GmbH & Co. KG specializes in the production of centrifugal pumps for industrial applications in chemical and petrochemical plants, fuel handling, heating oil systems, liquid LPG gas systems and others.

The company’s offer includes pumps with a volute casing, side channel pumps and multi-stage centrifugal pumps. These pumps are available in two versions: with mechanical sealing and with magnetic coupling. Magnetic coupling pumps, also known as sealless or hermetic pumps, are used wherever safety and reliability of installation operation is required, i.e. for all flammable, corrosive, toxic and environmentally harmful fluids.

Depending on the version, DICKOW pumps handle media with temperatures from -120°C to +400°C, working pressures up to 100 bar and capacities in the range from 0.1 to 1200 m3/h.

Files to downloadProducts

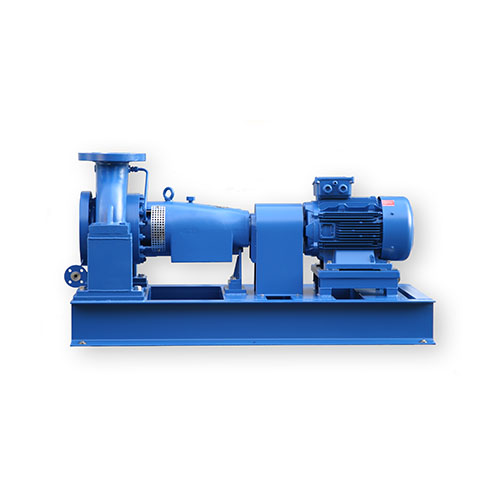

Volute casing pumps

Single stage with single or double mechanical seal.

With magnetic coupling

Design: according to EN22858, EN733, API610, API685

Delivered as complete pump sets.

Capacity: 2 to 900 m3/h

Pump head: up to 160 m

Temperature: up to +400°C

Options: vertical with long shaft, close coupled, with heating jacket, for explosion hazard zone

Tuthill GlobalGear® gear pumps

With magnetic coupling

Capacity: 3.7 to 32 m3/h

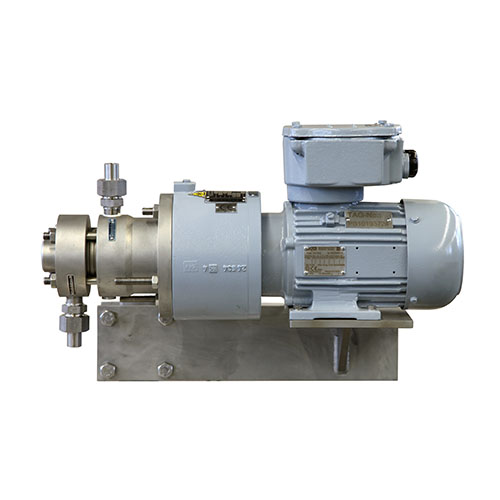

Side channel pumps

Single-stage or multi-stage

Self-priming, with low NPSHr value

With single or double mechanical seal

With magnetic coupling

Design: according to manufacturer’s standard

Supplied as complete pump sets

Capacity: 0.1 to 40 m3/h

Pump head: up to 400 m

Temperature: up to +180°C

Options: vertical with long shaft, close coupled, for explosion hazard

Centrifugal pumps

Single-stage or multi-stage

With single or double mechanical seal

With magnetic coupling

Design: according to the manufacturer’s standard

Supplied as complete pump sets

Capacity: up to 500 m3/h

Pump head: 460 m

Temperature: up to +180°C

Options: self-priming, with low NPSHr value, vertical with long shaft, close coupled, for explosion hazard zone, for boiling liquids or LPG