Manufacturer of louver and butterfly damper valves for IOS, flaps, valves and penstocks. Shut off and flow control of gases and liquids, biomass combustion.

Files to downloadIndustries

Products

Damper valve for flue gases and air

type DV

Function: shut-off and control

Range: DN50 – DN10 000

Pressure: < 0.5 bar

Temperature: -20°C to +1 000°C

Options: design for lower temperatures,

special linings for high temperatures

Louver damper valve for flue gases and air

type LDV

Function: shut-off and control

Range: < 13 000 x 13 000 mm

Pressure: < 0.5 bar

Temperature: -20°C to +1000°C

Options: design for lower temperatures,

special linings for high temperatures

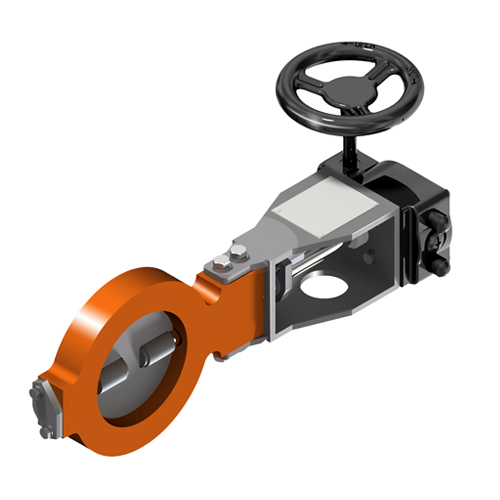

Wafer damper valve for flue gases and air

type DVH

Function: shut-off and control

Range: DN50 – DN1 000

Pressure: < 0.5 bar

Temperature: -20°C to +1 000°C

Options: design for lower temperatures,

special linings for high temperatures

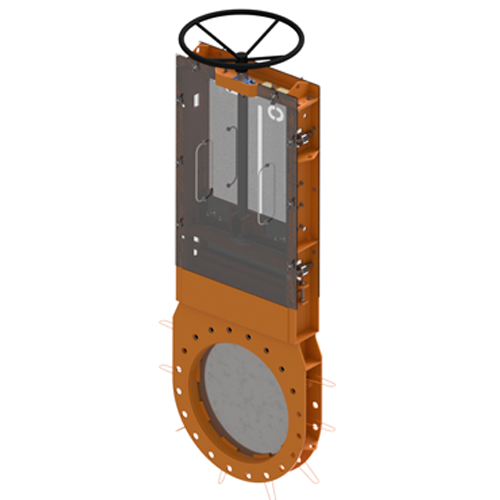

Guillotine damper

Guillotine damper

Function: shut off

Range: DN150 – DN6 000 GDV, GDV-T type

< 6,000 x 6,000 mm GDV, GDV-T type

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: tandem version with sealing air system, special lining for high temperatures

Diverter / 3-way valve

type DVR, DVR-T

Function: shut-off and control

Range: DN350–DN2 500

350 x 350 — 2500 x 2500 mm

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: tandem version with

sealing air system

Tandem damper with sealing air system

Range: DN200 – DN9600 DV-T type

12000 x 12000 mm LDV-T type

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: special linings (alloy and composite)

Drive: with emergency < 5s opening/closing function

T (Tandem) and DB (double blades) dampers with welded construction are used for

100% tight shut-off of the medium. For proper operation, they require the use of special sealing air system, which are also included in our offer.

Double blade damper with sealing air system

Function: shut off

Range: DN200–DN1000 DV-DB type

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: special linings (alloy and composite)

version for operation at low temperatures

Drive: with emergency < 5s opening/closing function

The requirement for tight shut-off of the media occurs in flue gas desulphurization, furnace dust removal, SO2, SO3, NOx gas handling systems, during sealing of technological processes, in metallurgy, chemistry, papermaking, glassworks, wood processing factories and other heavy industry facilities.

Safety and check valve

type CV

Function: control, safety

Range: DN200–DN2000

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: version for operation at low temperatures

discharge valves with adjustable counterweight for setting

Flap damper

Range: 200 x 200 — 6000 x 6000 mm FDV, FDV-T type

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: special linings (alloy and/or composite)

version for operation at low temperatures

version with internal insulation for gas turbine installations, with centric or off-centre propeller shaft

version for abrasive medium

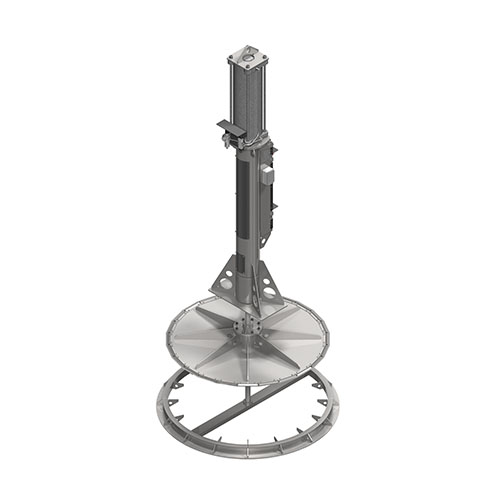

Poppet valve

Function: shut off

Range: DN350–DN3000 PDV, PDV-T type

(we can manufacture other irregular shapes of the duct)

Pressure: < 0.5 bar

Temperature: -20°C to +750°C

Options: version for operation at low temperatures

tandem version with sealing air system

Tunnel damper

Function: shut-off and control

Range: dimension on request LDVB type

Pressure: < 0.5 bar

Temperature: Resistance to +600° C for 120 min

SKID modules

Function: depends on customer requirements and system purpose.

In cooperation with our clients design office, we are also able to make modular systems — SKID. Due to wide design and implementation possibilities, we provide advanced systems designed for specific functionality. Our systems meet the requirements of various industry sectors and the destination process.

SKID systems that we also design and manufacture are sealing air systems used to create a barrier in Tandem (T) and Double Blade (DB) damper valves.

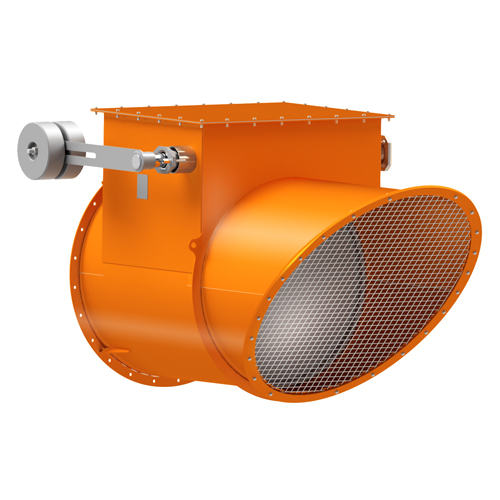

Sealing Air System (SAS or SKID)

Sealing Air System

Function: Preparation of sealing air for tandem and double blade dapers

Option: with sealing air heater

with steam heater

with centrifugal fan

with ducted axial fan

with comprehensive control and power systems

with additional sensors and/or measuring equipment

The sealing air system is designed to push air inside the tandem damper to ensure 100% tightness. The complete tightness of the air barrier is achieved by injecting air between two discs at an certain overpressure in relation to the pressure in the pipeline. Air SKIDs take care of the appropriate preparation of the sealing medium.